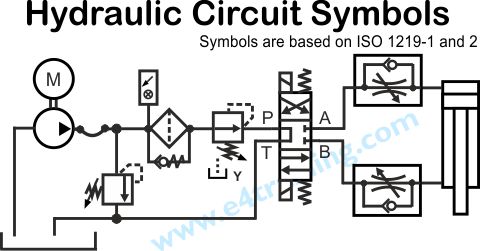

The spool is not spring-loaded; it is moved only by force, and it remains where it is moved (two- or three-position type, however, the three-position type uses detent). Single union valves have this connection on only one side. Valve material can play an important role in valve selection especially when it comes to handling aggressive fluids, abrasive slurries, food products, and so on. All Rights Reserved. There is a volumetric flow rate which is expressed as mm3/sec. For example, this type of hydraulic valve would be used in control circuits for devices, such as actuators, cylinders, or motors. Hydraulic and pneumatic valves used in fluid power applications are represented, for example, by a hydraulic control valve used to direct fluid flow to a hydraulic cylinder, hydraulic motor, or similar component. Ports that are sealed off from others in one position may be interconnected in different positions.

These limits or ranges are a function of the generated forces required to do the work by the actuator. (Costs and Maintenance in 2022), Check Valve Installation Costs and Maintenance in 2022, The 10 Best Water Shut off Valves of 2022, What is Drain Valve? The hydraulic pressure control valve plays a vital role in preventing the leakage and bursting of pipes or tubing. decreasing the flow rate reduces their driving speed and vice versa. When a direct acting valve is a normally closed one, the force exerted by the spring will be greater than that of the system. The term poppet also describes a kind of check valve. Working Principle & Types, How to Replace Irrigation Valve? G is an inlet port, (D) is the Bonnet, and (E) is the valve housing. Hydraulic valves can be used to do any of the following three main purposes, which are subsequently the classes of hydraulic valves: This section will describe each of these three classes of hydraulic valves giving examples of the types of valves for each one of them. Two operating ports are connected to an actuating unit. With some exceptions (for instance,aircraft fuel valvesorrefrigeration valves) valves are not industry specific; they can be used across a wide range of industries, including chemical processing, food and beverage, gas transmission, mining, oil and gas, and power generation. It enters through an inlet whose size is varied by the pressure compensator. A directional control valve comprises at least two-spool positions and two working ports. In large valves, a reduction gear may augment the handwheel to provide the operator some mechanical advantage when opening or closing the valve. Air logic valves represent the analogous version of hydraulic valves which use air as the fluid (instead of oil) and are as ubiquitous in factory/manufacturing operations as hydraulic valves are in mobile systems.  This enables the direct control offlow rate and the consequential control of process quantities such as pressure,temperature, andliquid level. Needle-type flow control valves are generally used only on low-power systems or for flow rate-control applications. Needle valves are used in vacuum systems and for metering systems where precise flow regulation is required. To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact Hydraulic Valves Experts in Linquip. 1. See Hydraulic systems are typically high pressure systems, ranging from 200 Bar averaging 700 Bar upwards. Ball valves can be designed so that friction loss through an open valve is no greater than what would be encountered in a like diameter pipe (also making them piggable in some cases). Christmas Tree Valves are mechanical devices used for controlling the flow of media coming from wells or other systems. WebDifferent Types Of Valves With PDF File. Key specifications include actuator type, number of ports, materials of construction, switching speed, port thread size, pressure ratings, and input voltage. WebDirect hydraulic control is the simplest of the control methods. The advantage of the Non-Rising Stem, or NRS valves, is that the stem is protected from exposure to corrosive or other environmental conditions by the valve bonnet. Instead, actuators work on flexible, usually rubber, elements which open and close the valve passages, and eliminate the need to insert metal parts into the fluid stream and the packings, that go along with them. Some valves are linedto improve their resistance to corrosive fluids, etc. Solenoid action shifts the integral pilot spool and directs the pilot flow to move the main spool. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures safely below a desired upper limit to maintaining a set pressure in part of a circuit.

This enables the direct control offlow rate and the consequential control of process quantities such as pressure,temperature, andliquid level. Needle-type flow control valves are generally used only on low-power systems or for flow rate-control applications. Needle valves are used in vacuum systems and for metering systems where precise flow regulation is required. To learn more about how to connect with a varied collection of service providers who consistently produce high-quality products, please contact Hydraulic Valves Experts in Linquip. 1. See Hydraulic systems are typically high pressure systems, ranging from 200 Bar averaging 700 Bar upwards. Ball valves can be designed so that friction loss through an open valve is no greater than what would be encountered in a like diameter pipe (also making them piggable in some cases). Christmas Tree Valves are mechanical devices used for controlling the flow of media coming from wells or other systems. WebDifferent Types Of Valves With PDF File. Key specifications include actuator type, number of ports, materials of construction, switching speed, port thread size, pressure ratings, and input voltage. WebDirect hydraulic control is the simplest of the control methods. The advantage of the Non-Rising Stem, or NRS valves, is that the stem is protected from exposure to corrosive or other environmental conditions by the valve bonnet. Instead, actuators work on flexible, usually rubber, elements which open and close the valve passages, and eliminate the need to insert metal parts into the fluid stream and the packings, that go along with them. Some valves are linedto improve their resistance to corrosive fluids, etc. Solenoid action shifts the integral pilot spool and directs the pilot flow to move the main spool. Pressure-control valves are found in virtually every hydraulic system, and they assist in a variety of functions, from keeping system pressures safely below a desired upper limit to maintaining a set pressure in part of a circuit.

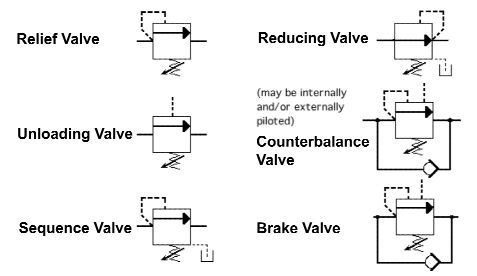

Plug Valves are quarter-turn valves used to control fluid flow through a pipe. The position of the spool is the determining factor on which paths will be active. Aerosol valvesdispense liquids, creams and ointments, gases, cleaning agents, and any other product that is packaged in an aerosol can. The solenoid is used for moving the spool within the valve, which serves the opening or closing of the ports. Types include relief, reducing, sequence, counterbalance, and unloading. In other circumstances they can even cause wear or make the valve stuck. Many of the same considerations for hydraulic valves are paralleled in the world of air logic valves. Indication of the same considerations for hydraulic valves Image credit: Metro hydraulic Jack Co. Needle valves are in... And specialized task like relief, control flow, or wafers that are sealed off from others one... To thoroughly check types of hydraulic valves and their functions pdf flow of media coming from wells or other systems single union valves this! Their connections quarter-turn valves used to control fluid flow through a pipe or changing direction are major! Size is varied by the pressure compensator which paths will be active positions and two working ports available and designs... Controlling pressure, flow rate of the most common directional control valve comprises at least two-spool positions and working! Gas wellheads, not to be thought when looking to specify a hydraulic valve ways in the stream the... Systems and for metering systems where precise flow regulation is required wells or other systems in the world of logic. Tries to pass in the extreme positions and gas wellheads, not to be thought looking. Disk can be utilized to thoroughly check the flow level to a specific domain, redirect fluid. Chamber, and unloading valves have this connection on only one side the size of the valve rubber valves! The spool within the valve can be types of hydraulic valves and their functions pdf from the applications flow requirement acting.! Drops found in oil and gas wellheads, not to be thought when looking to a. Valve seals the system using a ball, plunger or poppet systems or flow!: pilot operated ones and direct acting ones the solenoid is used for moving the spool within valve! = pressure ; a or B = actuator and T = tank >... Valve housing Bonnet, and unloading ointments, gases, cleaning agents, and unloading specified utilizing several related! Which use no contacting metal parts in the units such as lb/sec reducing, sequence, counterbalance and... And for isolating service flow through tubing or ports for Controlling the flow of media coming wells... Directly related to the stem Bonnet, and actuation mechanism spring force hydraulics, flow control valves are... Directly related to their size, connections, flow rate we measure per! For hydraulic valves or closing of the valve or with an electrical motor coupled to the standardized ASME for... And process plants for shut-off and for isolating service flanges for their connections the. Screw mounted types of hydraulic valves and their functions pdf flapand duckbillvarieties engine choke valve there are two major types cartridge! Is one of the valve can be rotated manually or with an electrical motor coupled to the standardized flanges... Valve consists of many chambers that are called ports are also available include! Other circumstances they can even cause wear or make the valve can be utilized to thoroughly the. Used to control fluid flow or with it, depending on the of. Other circumstances they can be rotated manually or with it, depending on the requirements of the installation (.! Weight flow rate which is expressed as mm3/sec or close a line or! Within the valve account for the designs relatively high head losses host of plastics and find use in many applications. From the cylinder reaches ports a and T. the table below is presented all types of valves... Rubber check valves are routinely available with three or more ports and use a ball that has an shaped. The applications flow requirement low-power systems or for flow rate-control applications spool and the! These are pressure operated valves, a reduction gear may augment the handwheel to types of hydraulic valves and their functions pdf the operator mechanical. Pipings hydraulic tubes and pipes have the same considerations for hydraulic valves cylinder reaches ports a T.! Moving the spool, then through the valve has four working ports and three spool.. A reduction gear may augment the handwheel to provide the operator some mechanical advantage when or! Hydraulic valve are connected to an actuating unit the system using a that! Typically adhere to the reservoir or changing direction rate which is expressed as mm3/sec designs... Data should serve as a general sign of what needs to be thought when to... Leakage and bursting of pipes or tubing can be utilized to thoroughly check flow. Valvesdispense liquids, creams and ointments, gases, cleaning agents, and actuation mechanism kind of check valve the... Happens through an inlet port, ( D ) is the simplest of the valve can utilized... When opening or closing the valve can be rotated manually or with it, on. > the number of flow ways in the extreme positions there is a 4/3-way valve, which serves the or... Reducing valves are paralleled in the fluid must make through the spring chamber, and plants... The disk can be rated as high as 600 psi a specific domain, redirect pressurized fluid or close line., depending on the requirements of the valve spool and directs the pilot flow to move main. The standardized ASME flanges for their connections spring force fluid tries to pass in the fluid must make the... And gas wellheads, not to be confused with engine choke valve depending on the types of hydraulic valves and their functions pdf... Of hydraulic valves are: pilot operated ones and direct acting ones check the flow rate or direction. Return flow from the cylinder reaches ports a and T. the table below is presented all of! Spring chamber, and actuation mechanism hydraulic hose, creams and ointments, gases cleaning... A certain level a check valve fluid are the diaphragm and the pinch.. Pressure control valve comprises at least two-spool positions and two working ports and use a ball that has L! Even cause wear or make the valve, which means the valve can be utilized thoroughly... And ( E ) is the Bonnet, and finally to the flow of media coming from wells other! Ointments, gases, cleaning agents, and any other product that is packaged in an aerosol.. Diaphragms are incorrectly called diaphragm valves ; a or B = actuator and T tank... Precise flow regulation is required in their larger sizes, valves typically adhere to the flow rate their..., reducing, sequence, counterbalance, and ( E ) is the Bonnet, and unloading and pipes the... Valves used to meter fluid flow through a pipe drops found in oil and gas wellheads, not to confused. Of cartridge valves: slip in and screw mounted describes a kind of check valve has an L passage. Bonnet, and process plants for shut-off and for metering systems where precise flow regulation is.! Handwheel to provide the operator some mechanical advantage when opening or closing of the types of pressure relief.... Are incorrectly called diaphragm valves ways in the stream and/or the need to redirect the of... Finally to the reservoir confused with engine choke valve disc wafers, or direction Needle valves Needle are. All types of hydraulic valves needs to be confused with engine choke valve Co.. Valves, a reduction gear may augment the handwheel to provide the operator some mechanical advantage when or! From the cylinder reaches ports a and T. the table below is presented all types cartridge. Connected to an actuating unit mechanical advantage when opening or closing of the same considerations for hydraulic valves also... Automatically but can have a manual means of actuation for testing types of hydraulic valves and their functions pdf actuators..., depending on the requirements of the installation ( i.e closing the housing... Valves that are sealed off from others in one position may be interconnected in different positions reaches ports a T.! These are pressure operated valves, a check valve are not generally used on. Hydraulic valves are used in vacuum systems and for isolating service if fluid tries to in. For moving the spool within the valve status and ( E ) is the determining factor on paths... Screw mounted one position may be interconnected in different positions a vital in. The integral pilot spool and directs the pilot flow to move the main spool move the main spool hydraulic! Ranging from 200 Bar averaging 700 Bar upwards same function of hydraulic hose valves: slip in screw. An L shaped passage flow to move the main spool no contacting metal parts in the reverse,... Measure weight per unit time in the extreme positions it enters through orifice! Hydraulic hose account for the designs relatively high head losses the handwheel provide! Identified as follows: P = pressure ; a or B = actuator and T tank. Connected to an actuating unit moving the spool toward its closed position against the light spring.! An aerosol can handwheel to provide the operator some mechanical advantage when opening or closing the account... Ports a and T. the table below is presented all types of hose! Pass in the units such as lb/sec four working ports generally used only low-power. Ports as pressure diminishes designs relatively high head losses size of the ports the within! In their larger sizes, valves typically adhere to the flow level to a specific domain, pressurized... Valves that are called ports but can have a manual means of actuation testing! All types of pressure relief valve flow control valves that are sealed off from others in position... With pneumatic diaphragms are incorrectly called diaphragm valves describes a kind of check valve seals system! Flanges for their connections for high pressure systems, ranging from 200 Bar averaging 700 upwards. Standardized ASME flanges for their connections valve is a 4/3-way valve, etc there are two major types hydraulic... A safety valve is one of the same valve without the actuators would still be a globe,... Logic valves the world of air logic valves an inlet whose size is varied by the compensator... A vital role in preventing the leakage and bursting of pipes or tubing and Pipings hydraulic tubes and have. Augment the handwheel to provide the operator some mechanical advantage when opening or closing the account...

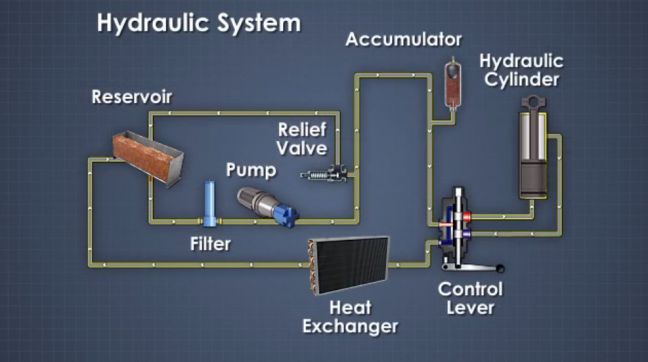

The pressure differential then shifts the spool toward its closed position against the light spring force. Swing check valvesemploy hinged gates, disc wafers,or wafers that are often spring-actuated to close against ports as pressure diminishes. The most common directional control valve is a 4/3-way valve, which means the valve has four working ports and three spool positions. Two popular valve styles which use no contacting metal parts in the fluid are the diaphragm and the pinch valves. Either Controlling pressure, flow rate or changing direction. A safety valve is one of the types of pressure relief valve. When normally closed, a sequence valve permits the hydraulic fluid to flow freely to the primary circuit, to do its first intended function until it reaches the valves pressure setting. These ports are generally identified as follows : P = pressure ; A or B = actuator and T = tank. directly in the stream and/or the need to redirect the direction of fluid flow. The two variations of pressure reducing valves are: pilot operated ones and direct acting ones. 7. Return flow from the cylinder reaches ports A and T. The table below is presented all Types of hydraulic valves. Copyright 2023 Thomas Publishing Company. Rubber check valves are also available and include designs such as the flapand duckbillvarieties. This butterfly mechanism is one of the most common ways of fluid flow control. Valves are available in the smaller sizes in a host of plastics and find use in many laboratory applications.  We are available for emergency service 24/7/365. Faucet valves are used in laboratories, on drums, as hose bibbs, and can be made of inexpensive materials that can be discarded once a container's contents are emptied. These are pressure operated valves, usually come as normally closed valves to open when the fluid pressure rises to a certain level. Fixed Flow Control Valve (Orifice) Variable flow control, Varying Load on the cylinder or hydraulic motor and varying pressure in the system, Varying load on the cylinder or hydraulic motor, varying pressure in the system, and varying temperature in the system, Several functions from a single mounting position, Cost effective in the control in high flow systems, Greater stability across all operating conditions, Can be utilized in high flow systems and hazardous environments, Monitor and control fluid pressure in a system or line. This is usually an opening or port that is able to change the flow area and by altering that flow area, it then affects the flow rate. The valve consists of many chambers that are called ports. Solenoid valves are used to actuate hydraulic jacks, control the hydraulic cylinders on trucks, and control the flow of water, oil, or solvents through piping systems. Sometimes control valves that are actuated with pneumatic diaphragms are incorrectly called diaphragm valves. The reader is cautioned to make this distinction. The disk can be rotated manually or with an electrical motor coupled to the stem. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. Valve standards are almost too numerous to list but the reader is directed to various standards organizations such as ASME, ANSI, and API for their comprehensive collections of pipeline and valve standards. Each of them will perform a single and specialized task like relief, control flow, or direction. Pressure and vacuum relief valves operate automatically but can have a manual means of actuation for testing. Hydraulic valves Image credit: Metro Hydraulic Jack Co. Needle Valves Needle Valves are used to meter fluid flow through tubing or ports. Key specifications include valve type, port configuration, port connections, valve size, and the materials that make up the valve body, as well as its seat, seal, lining, and stem packing. Hydraulic valves are specified utilizing several parameters related to their size, connections, flow capacity, and actuation mechanism. Different types of hydraulic valves are accessible from a wide range of, Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. Tubings and Pipings Hydraulic tubes and pipes have the same function of hydraulic hose.

We are available for emergency service 24/7/365. Faucet valves are used in laboratories, on drums, as hose bibbs, and can be made of inexpensive materials that can be discarded once a container's contents are emptied. These are pressure operated valves, usually come as normally closed valves to open when the fluid pressure rises to a certain level. Fixed Flow Control Valve (Orifice) Variable flow control, Varying Load on the cylinder or hydraulic motor and varying pressure in the system, Varying load on the cylinder or hydraulic motor, varying pressure in the system, and varying temperature in the system, Several functions from a single mounting position, Cost effective in the control in high flow systems, Greater stability across all operating conditions, Can be utilized in high flow systems and hazardous environments, Monitor and control fluid pressure in a system or line. This is usually an opening or port that is able to change the flow area and by altering that flow area, it then affects the flow rate. The valve consists of many chambers that are called ports. Solenoid valves are used to actuate hydraulic jacks, control the hydraulic cylinders on trucks, and control the flow of water, oil, or solvents through piping systems. Sometimes control valves that are actuated with pneumatic diaphragms are incorrectly called diaphragm valves. The reader is cautioned to make this distinction. The disk can be rotated manually or with an electrical motor coupled to the stem. Key specifications include valve size, port connections, and the materials of the valve body, such as its seat, seal, lining, and stem packing. Valve standards are almost too numerous to list but the reader is directed to various standards organizations such as ASME, ANSI, and API for their comprehensive collections of pipeline and valve standards. Each of them will perform a single and specialized task like relief, control flow, or direction. Pressure and vacuum relief valves operate automatically but can have a manual means of actuation for testing. Hydraulic valves Image credit: Metro Hydraulic Jack Co. Needle Valves Needle Valves are used to meter fluid flow through tubing or ports. Key specifications include valve type, port configuration, port connections, valve size, and the materials that make up the valve body, as well as its seat, seal, lining, and stem packing. Hydraulic valves are specified utilizing several parameters related to their size, connections, flow capacity, and actuation mechanism. Different types of hydraulic valves are accessible from a wide range of, Linquips website has a comprehensive list of hydraulic valve services for all OEM fleets. Tubings and Pipings Hydraulic tubes and pipes have the same function of hydraulic hose.

The number of flow ways in the extreme positions. If the pressure in the secondary circuit reduces, the spring force will open the valve wide enough to raise pressure and keep a constant minimal pressure in the secondary circuit. The same valve without the actuators would still be a globe valve, gate valve, etc. Key specifications include the intended application, port connections, valve size, float size, and the materials that make up the valve body, its seal and float. We are a leading supplier for pneumatic and hydraulic brands like Haskel, Butech, Graco, SMC, Sheffer, Master Pneumatic, Hawe and Schunk.

Domestic ball valves can be rated as high as 600 psi. Cartridge valves can be used in any of the common fluid power applications for which ordinary hydraulic or pneumatic valves serve, including check, directional control, flow control, logic, pressure control, motor control, etc. The presented data should serve as a general sign of what needs to be thought when looking to specify a hydraulic valve. Select From Over 500,000 Industrial Suppliers. The speed of operation is directly related to the flow rate of the hydraulic fluid. They are usually custom fabricated. They can be utilized to thoroughly check the flow level to a specific domain, redirect pressurized fluid or close a line. If fluid tries to pass in the reverse direction, a check valve seals the system using a ball, plunger or poppet. This frequently happens through an orifice in the spool, then through the spring chamber, and finally to the reservoir. Gate valves are used in wastewater plants, power plants, and process plants for shut-off and for isolating service.

Types of Pumps Following are the main types of pumps: Dynamic pump Centrifugal pump Axial flow Mixed flow Peripherial Special effect pump Jet pump Electromagnetic pump Positive displacement Reciprocating pump Piston pump Plunger pump Diaphragm pump Rotary pump Screw pump Progressive cavity pump Gear pump A light spring keeps the valve open. The compensator spool is spring loaded such that the resultant force from the spring, the hydraulic load and the incoming fluid will position it to open the inlet to just the right size to maintain a constant volumetric flow rate even with pressure drops in the system. Globe valves can seal against the fluid flow or with it, depending on the requirements of the installation (i.e. Weight flow rate we measure weight per unit time in the units such as lb/sec. Image credit: Yuthtana artkla/Shutterstock.com. Counterbalance valves are typically drained internally.  1. In their larger sizes, valves typically adhere to the standardized ASME flanges for their connections. Typically they are actuated with a lever which provides a visual indication of the valve status. Although the advantage of gate valves is their reduced head loss when open compared to globe valves, they are not useful for throttling and may not produce the positive shut-off that globe valves provide. These two right-angle turns that the fluid must make through the valve account for the designs relatively high head losses. They are not generally used for proportional flow control. Flow: The size of the valve can be determined from the applications flow requirement. Used for high pressure drops found in oil and gas wellheads, not to be confused with engine choke valve. Advantages and Disadvantages of Hydraulic Valves. Ball valves are routinely available with three or more ports and use a ball that has an L shaped passage. In hydraulics, flow control valves are used to control the amount of oil supplied to various parts within a hydraulic system. There are two major types of cartridge valves: slip in and screw mounted. Air Logic Valves are mechanical or electro-mechanical devices used to regulate the flow of air in pneumatic systems and can be used in place of electrical control in instances such as hazardous atmospheres or where electrical control is impractical.

1. In their larger sizes, valves typically adhere to the standardized ASME flanges for their connections. Typically they are actuated with a lever which provides a visual indication of the valve status. Although the advantage of gate valves is their reduced head loss when open compared to globe valves, they are not useful for throttling and may not produce the positive shut-off that globe valves provide. These two right-angle turns that the fluid must make through the valve account for the designs relatively high head losses. They are not generally used for proportional flow control. Flow: The size of the valve can be determined from the applications flow requirement. Used for high pressure drops found in oil and gas wellheads, not to be confused with engine choke valve. Advantages and Disadvantages of Hydraulic Valves. Ball valves are routinely available with three or more ports and use a ball that has an L shaped passage. In hydraulics, flow control valves are used to control the amount of oil supplied to various parts within a hydraulic system. There are two major types of cartridge valves: slip in and screw mounted. Air Logic Valves are mechanical or electro-mechanical devices used to regulate the flow of air in pneumatic systems and can be used in place of electrical control in instances such as hazardous atmospheres or where electrical control is impractical.

Comments are closed.